dec . 21, 2024 14:54 Back to list

remnant galvanized iron manufacturers

The Rise of Remnant Galvanized Iron A Closer Look at Manufacturers

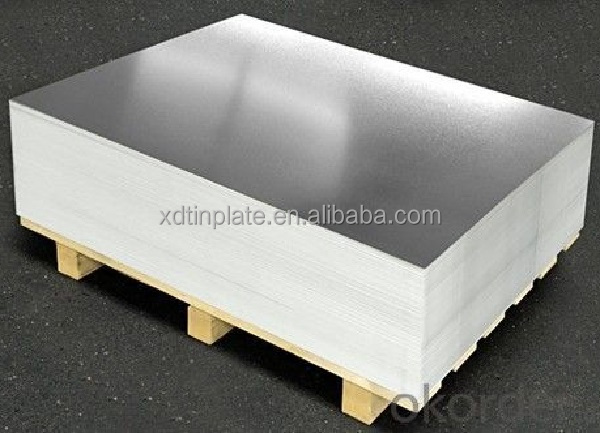

In the ever-evolving world of construction and manufacturing, galvanized iron has emerged as an indispensable material. Known for its corrosion resistance and durability, galvanized iron is commonly used in various applications, from roofing to fencing. However, in recent years, a niche segment known as remnant galvanized iron has gained traction among manufacturers and consumers alike. This article explores the significance, benefits, and growing popularity of remnant galvanized iron, along with the role of manufacturers in this specialized market.

Understanding Remnant Galvanized Iron

Remnant galvanized iron refers to leftover pieces or scraps of galvanized iron that are generated during the manufacturing process. These remnants can vary in size, thickness, and shape but still retain the essential properties that make galvanized iron a preferred choice in many industries. With a focus on sustainability and resource efficiency, the utilization of remnant galvanized iron is becoming a trend among manufacturers looking to minimize waste and reduce production costs.

Benefits of Using Remnant Galvanized Iron

1. Cost-Effectiveness One of the most significant advantages of using remnant galvanized iron is its cost-effectiveness. Manufacturers can purchase these remnants at a lower price compared to new materials. This cost saving can be passed on to consumers, making projects more affordable.

2. Sustainability In an age where environmental concerns are at the forefront, the use of remnant galvanized iron aligns with sustainable practices. By utilizing leftover materials, manufacturers contribute to reducing waste in landfills and minimizing the overall environmental footprint of their production processes.

3. Versatility Remnant galvanized iron can be utilized in various applications. From constructing smaller structures or fixtures to custom projects, its versatility makes it an attractive option for both manufacturers and builders. The variety in shapes and sizes allows for creative solutions to meet specific project requirements.

4. Quality Assurance Despite being remnants, these pieces often maintain high quality. Manufacturers who deal with remnant galvanized iron take care to ensure that the scraps are usable and meet industry standards. This attention to quality ensures that end users receive reliable and durable products.

remnant galvanized iron manufacturers

Role of Manufacturers

Manufacturers play a crucial role in the remnant galvanized iron market. Their efforts not only help in processing and repurposing these materials but also in educating consumers about their benefits and applications. Here are some ways manufacturers contribute to the growth of this segment

1. Recycling and Processing Many manufacturers have established systems to collect, process, and distribute remnants from their production lines. By doing so, they help create a circular economy where materials are reused rather than discarded.

2. Innovation in Design Manufacturers are increasingly innovating in their designs to incorporate remnant galvanized iron into their products. This design approach allows for unique creations while using materials that might otherwise go to waste.

3. Market Expansion With a growing awareness of sustainability, manufacturers are expanding their product lines to include remnant galvanized iron. They are also reaching out to new markets, such as DIY enthusiasts and smaller construction projects, where these materials can be particularly advantageous.

4. Education and Advocacy Manufacturers also play a role in educating the market about the benefits and potential uses of remnant galvanized iron. By providing information and resources, they help consumers make informed decisions and advocate for more sustainable building practices.

Conclusion

The rise of remnant galvanized iron presents a myriad of opportunities for manufacturers and consumers alike. Its cost-effectiveness, sustainability, and versatility make it an appealing option in today’s market. As more manufacturers embrace this trend, we can expect to see increased innovation and wider usage of remnant galvanized iron in various applications. By overcoming traditional notions about scraps, manufacturers can lead the way toward a more sustainable future in the construction and manufacturing industries. The journey of remnant galvanized iron is just beginning, and its potential is as vast as the ingenuity of those who choose to utilize it.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025