nov . 25, 2024 21:09 Back to list

coca cola puzzle in tin can suppliers

The Coca-Cola Puzzle in Tin Can Suppliers

In the world of beverage production, few brands stand out as prominently as Coca-Cola. Its ubiquitous presence in markets across the globe speaks volumes about its success, particularly in the realm of packaging. One of the most interesting aspects of Coca-Cola’s supply chain is how it sources its tin can suppliers, a topic that may appear mundane at first but is fraught with strategic puzzles and challenges.

The journey of Coca-Cola’s beverages begins with one of the most fundamental questions of production how to effectively package its drinks while ensuring quality, sustainability, and cost-efficiency. This challenge is magnified by the sheer volume of products that Coca-Cola produces and the global demand for its signature taste. As a result, the company has developed a complex network of tin can suppliers, each playing a crucial role in the overall manufacturing process.

Sustainability Matters

Today, Coca-Cola has a strong commitment to sustainability, which heavily influences its choice of suppliers. The production of tin cans involves significant resources, including metal and energy. Coca-Cola places emphasis on partnering with suppliers who adhere to sustainable practices, such as using recycled materials or implementing energy-efficient manufacturing processes. This not only reduces the environmental impact but also aligns with the brand's corporate responsibility goals.

In recent years, there has been a growing trend toward producing cans made from recycled aluminum. Coca-Cola recognizes that utilizing recycled materials not only reduces carbon emissions but also resonates with consumers who are increasingly concerned about environmental issues. This innovative approach contributes to Coca-Cola’s long-term strategy of creating a circular economy that benefits both the company and the planet.

Quality Control Challenges

Another critical aspect of tin can suppliers is the consistent maintenance of quality standards. Coca-Cola’s reputation is built on the quality of its products, and any compromise in packaging can lead to customer dissatisfaction. Thus, the company must rigorously vet its suppliers, ensuring that they meet or exceed stringent quality benchmarks. This involves regular audits, quality inspections, and collaboration to address any issues immediately.

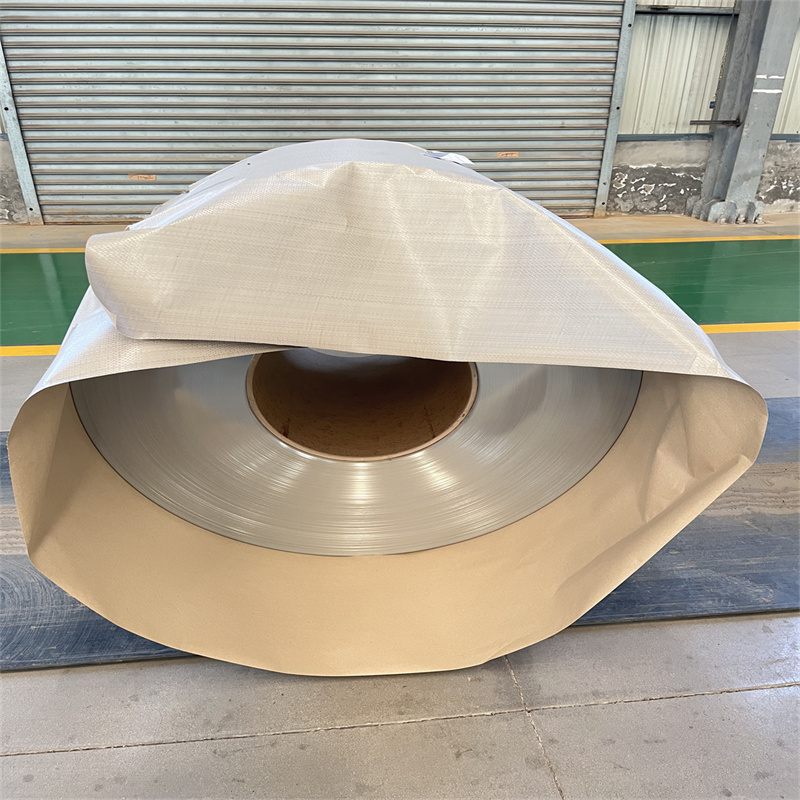

coca cola puzzle in tin can suppliers

Coca-Cola's requirements often lead to a complex interplay between suppliers. For instance, if one supplier cannot meet demand due to production issues, Coca-Cola must have contingency plans in place to source cans from another vendor. This level of coordination requires not only strong relationships but also thoughtful negotiation tactics. The challenge becomes ensuring that suppliers can scale operations effectively, especially during peak times, such as summer or holiday seasons when demand surges.

The Economics of Supply

The economics of tin can supply is another layer of this intricate puzzle. Price volatility in the metals market means that Coca-Cola faces fluctuating costs associated with raw materials. This can significantly affect the bottom line, prompting the company to adopt financial strategies such as hedging against metal price increases. Moreover, Coca-Cola’s extensive global reach necessitates that the company continually evaluate its supplier locations to optimize logistics and reduce transportation costs.

In addition, Coca-Cola employs advanced forecasting methods, using data analytics to predict consumer demand, thus allowing suppliers to align their production schedules and ensure timely delivery. This analytical approach not only improves efficiency but also helps in building stronger partnerships with suppliers, as both parties work towards a common goal.

Conclusion

The world of Coca-Cola’s tin can suppliers is anything but straightforward. With sustainability at the forefront, stringent quality control measures in place, and the complexities of economic fluctuations, Coca-Cola navigates a multifaceted supply chain designed to ensure both product integrity and environmental responsibility. As consumer preferences continue to evolve, the company’s ability to adapt and innovate within this supply chain will be pivotal for its ongoing success.

In unpacking the Coca-Cola puzzle regarding tin can suppliers, one realizes that the interplay between operational efficiency, sustainability, and strategic partnerships is integral to maintaining the brand’s leadership position in the beverage industry. The challenges are many, but so are the solutions, as Coca-Cola continues to refresh not just its products, but also its commitment to sustainable practices and quality excellence.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025