Νοέ . 22, 2024 20:42 Back to list

water tin can factories

The Role of Water in Tin Can Factories A Critical Resource

The manufacturing of tin cans is a complex process that involves various stages, each critical to the creation of a product that is both functional and environmentally friendly. Among the various resources required in this production process, water plays a vital role. Understanding the significance of water in tin can factories not only sheds light on the manufacturing process but also emphasizes the need for sustainable practices in industrial operations.

The Manufacturing Process of Tin Cans

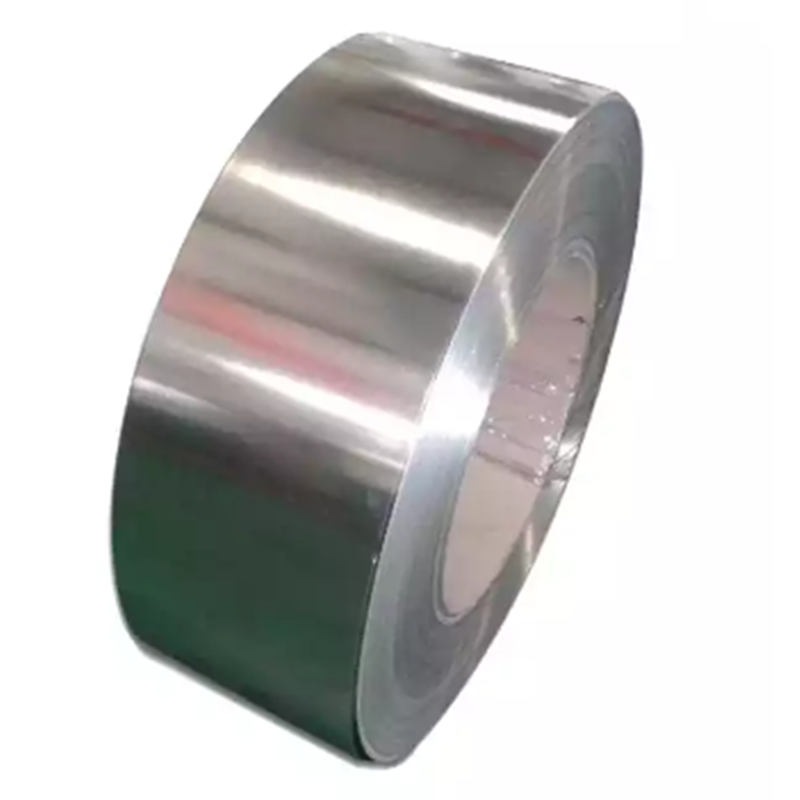

Tin cans are predominantly made from steel, which is coated with tin to prevent corrosion. The journey from raw materials to the final product involves several stages, including metal forming, coating, and packaging. Each of these stages relies heavily on water for different functions.

1. Cooling One of the essential roles of water in tin can manufacturing is its use in cooling processes. During the metal forming stage, high temperatures are required to mold the metal into the desired shape. Cooling water is employed to rapidly lower the temperature of the metal, ensuring it hardens correctly without defects.

2. Cleaning Water is also crucial for cleaning the surfaces of the metal sheets before they undergo the coating process. Removing any contaminants, such as oils or dust, ensures that the tin adheres properly to the surface of the steel. This step is vital for the longevity and integrity of the tin can.

3. Coating The application of the tin coating itself often requires water-based solutions. This stage is critical, as it protects the steel from rust and enhances the can's appearance. Water may be used as a medium for transporting coatings or as a cleaning agent for equipment used in the coating application.

4. Waste Management In the context of sustainability, water also relates to the management of waste produced during the manufacturing process. Wastewater can contain remnants of chemicals used in cleaning and coating, thus necessitating proper treatment before its release back into the environment. Efficient water management practices are essential not just for compliance with regulations, but also for minimizing the factory's environmental footprint.

water tin can factories

Sustainable Practices

The importance of water in tin can factories brings to light several challenges and opportunities regarding sustainability. As industries face increasing scrutiny over their resource consumption, the need for water conservation becomes paramount.

1. Recycling Water Many modern tin can factories are investing in water recycling systems. By treating and reusing process water, these facilities can significantly reduce their overall consumption and minimize waste. Techniques such as reverse osmosis and advanced filtration systems are being implemented to ensure that water is reused wherever possible.

2. Rainwater Harvesting Some companies are exploring the potential of rainwater harvesting as a supplementary water source. This practice not only helps in conserving municipal water but also reduces the risk of water shortages during dry seasons.

3. Employee Training and Awareness Educating employees about the importance of water conservation and efficient usage can lead to significant improvements in water management. Regular training sessions can encourage staff to identify and report leaks, optimize water usage in their tasks, and contribute to a culture of sustainability.

Conclusion

Water is an indispensable resource in the production of tin cans, influencing various stages of the manufacturing process. However, like many industries, tin can factories must recognize their responsibility towards sustainable water management. By adopting innovative practices such as water recycling, rainwater harvesting, and comprehensive employee training, these factories can contribute significantly to environmental sustainability while maintaining efficient production processes. As the demand for eco-friendly packaging continues to rise, the role of water in tin can manufacturing will remain a critical focal point for both industry leaders and consumers alike.

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025

-

China 14 ft Metal Roofing Price Factory | Durable & Affordable

NewsJul.28,2025