Ιαν . 10, 2025 12:40 Back to list

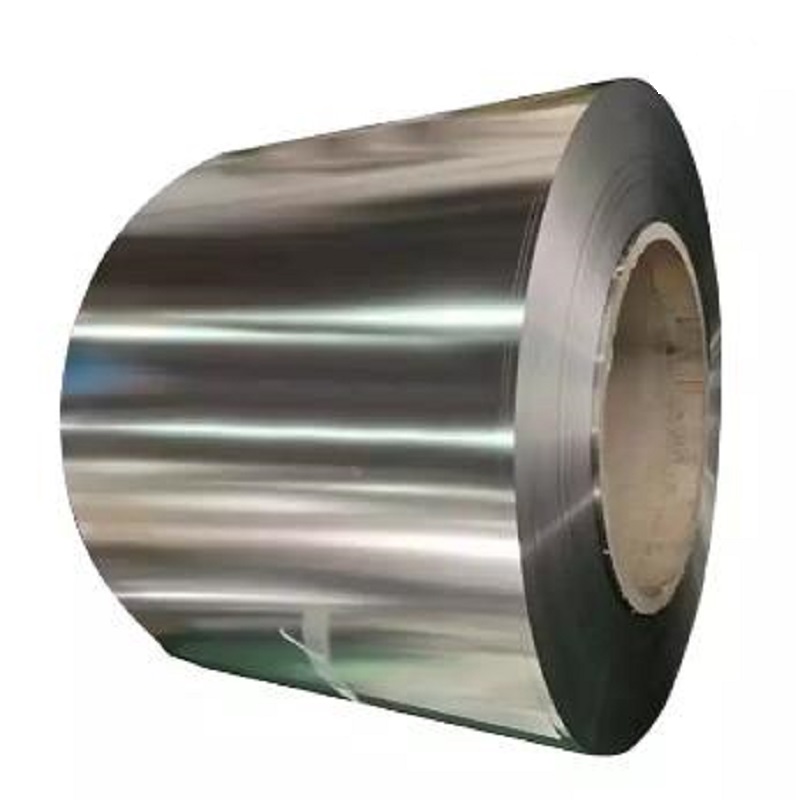

tin plates factories

Navigating the world of tin plates factories involves delving deep into a highly specialized and precise manufacturing industry. In the global arena of metal fabrication, tin plates have emerged as a pivotal product due to their versatile applications, notably in food packaging, electronics, and decorative materials. The successful production of tin plates rests on the expertise and reliability of manufacturing plants designed specifically for this task.

Trustworthiness is cultivated through transparent business relationships and ethical manufacturing practices that prioritize both client needs and environmental responsibilities. Reliable factories often maintain rigorous traceability systems to monitor every phase of production, ensuring accountability and quality assurance. Additionally, fostering an open dialogue with clients through timely communication and feedback mechanisms establishes a brand identity grounded in trust. In selecting tin plates factories, stakeholders should critically assess these facilities on their ability to balance innovation with stability. It's not merely about output quantity but the capability to deliver products that consistently meet or exceed client expectations. Investing time in understanding a factory’s production ethos – from the raw material sourcing strategies to the implementation of cutting-edge technological advancements – is key to securing a partnership that benefits all parties involved. By focusing on a combination of experienced craftsmanship, authoritative practices, and trust-centric relationships, the modern tin plates factory is well-positioned to not only meet existing industrial demands but also pioneer new frontiers in metal packaging solutions. For industries reliant on these materials, choosing the right manufacturing partner means harnessing quality, safety, and sustainability all rolled into one, a prospect that can significantly elevate product standards and market competitiveness.

Trustworthiness is cultivated through transparent business relationships and ethical manufacturing practices that prioritize both client needs and environmental responsibilities. Reliable factories often maintain rigorous traceability systems to monitor every phase of production, ensuring accountability and quality assurance. Additionally, fostering an open dialogue with clients through timely communication and feedback mechanisms establishes a brand identity grounded in trust. In selecting tin plates factories, stakeholders should critically assess these facilities on their ability to balance innovation with stability. It's not merely about output quantity but the capability to deliver products that consistently meet or exceed client expectations. Investing time in understanding a factory’s production ethos – from the raw material sourcing strategies to the implementation of cutting-edge technological advancements – is key to securing a partnership that benefits all parties involved. By focusing on a combination of experienced craftsmanship, authoritative practices, and trust-centric relationships, the modern tin plates factory is well-positioned to not only meet existing industrial demands but also pioneer new frontiers in metal packaging solutions. For industries reliant on these materials, choosing the right manufacturing partner means harnessing quality, safety, and sustainability all rolled into one, a prospect that can significantly elevate product standards and market competitiveness.

Latest news

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025