Οκτ . 06, 2024 01:02 Back to list

galvanized malleable iron fittings manufacturers

Understanding Galvanized Malleable Iron Fittings Manufacturers and Their Role

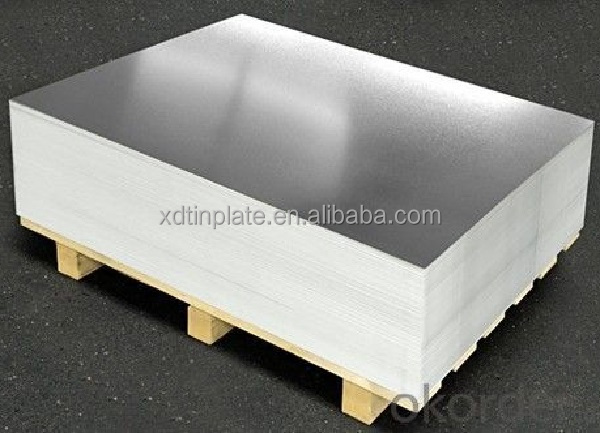

Galvanized malleable iron fittings are essential components widely used in various plumbing and construction applications. These fittings are created from malleable iron, which is a type of cast iron that has been heat-treated to improve its ductility and toughness. The galvanization process involves coating the fittings with zinc, which adds an extra layer of protection against corrosion and enhances their durability. As the demand for high-quality plumbing and structural solutions grows, manufacturers specializing in galvanized malleable iron fittings have become increasingly important in the industry.

Why Choose Galvanized Malleable Iron Fittings?

One of the primary reasons for selecting galvanized malleable iron fittings is their impressive mechanical properties. Malleable iron has excellent tensile strength, providing reliable support and a long-lasting solution for various piping needs. The galvanization not only protects the fittings from rust and corrosion but also extends their lifespan, making them ideal for both indoor and outdoor applications.

These fittings are particularly popular in the construction, oil and gas, and agricultural sectors. They are commonly used in water and gas pipelines, HVAC systems, and various other industrial applications. The versatility of galvanized malleable iron fittings makes them suitable for high-pressure environments, where durability and reliability are paramount.

Manufacturers' Expertise

Manufacturers of galvanized malleable iron fittings play a crucial role in ensuring that these products meet industry standards and specifications. The process of production requires advanced techniques and knowledge of metallurgy and engineering to create fittings that can withstand varying stress and environmental conditions.

galvanized malleable iron fittings manufacturers

Leading manufacturers often invest in modern technologies and quality control processes to ensure that their products are reliable. They conduct rigorous testing to verify the strength and corrosion resistance of the fittings, ensuring that they can perform effectively in their intended applications. By adhering to international standards such as ASTM and ISO, these manufacturers guarantee the quality and safety of their products.

Sustainability and Innovation

As environmental concerns become more prevalent, manufacturers in this sector are also focusing on sustainable practices. Many companies are adopting eco-friendly production methods and utilizing recycled materials, which not only reduce waste but also lower the carbon footprint of the manufacturing process.

Innovation is another key aspect of the industry. Manufacturers are continually researching and developing new products to enhance the performance of galvanized malleable iron fittings. This includes improving the coating processes for better corrosion resistance and exploring new designs that meet specific customer needs.

Conclusion

In summary, galvanized malleable iron fittings are a vital part of modern infrastructure, offering strength, durability, and resistance to corrosion. Manufacturers specializing in these products are essential for meeting the diverse requirements of various industries. By focusing on quality, sustainability, and innovation, these manufacturers are helping to shape a robust and environmentally conscious future for construction and plumbing solutions. Whether for residential, commercial, or industrial use, selecting the right fitting from a reputable manufacturer can make all the difference in the longevity and safety of any project.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025