Νοέ . 15, 2024 11:23 Back to list

galvanized iron coil quotes supplier

Understanding Galvanized Iron Coil Supply and Pricing

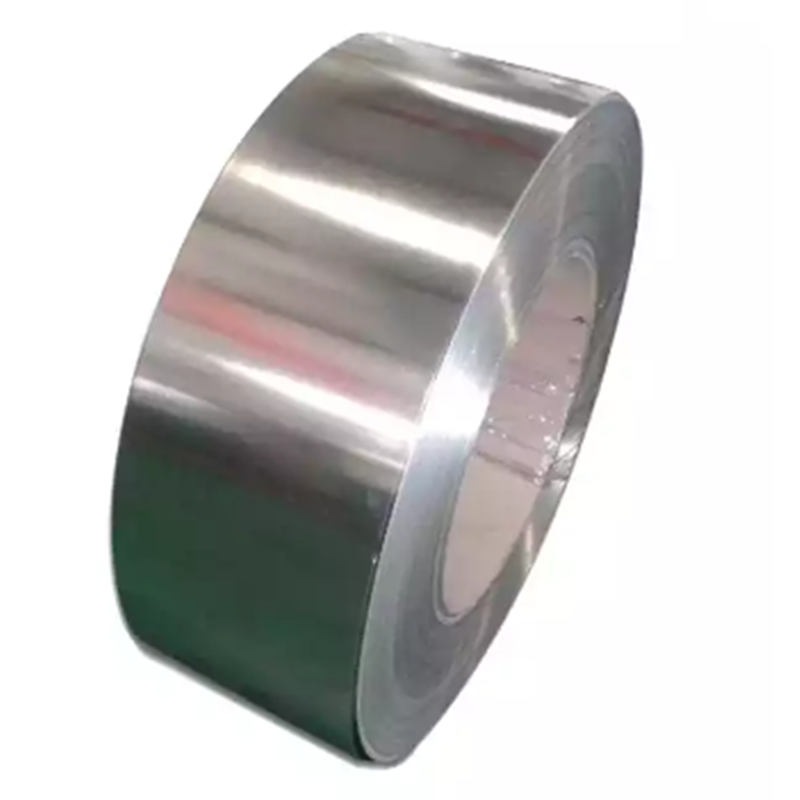

Galvanized iron coils are a vital component in various industries, renowned for their durability, resistance to corrosion, and versatile applications. The galvanized coating, made of zinc, provides a protective layer that prolongs the lifespan of the iron, making it an excellent choice for construction, automotive, and manufacturing sectors. As the demand for galvanized iron coils continues to grow, understanding suppliers and the factors that influence pricing is essential for businesses looking to make informed purchasing decisions.

What are Galvanized Iron Coils?

Galvanized iron coils are sheets of iron or steel coated in zinc to prevent rust and degradation. They are available in various thicknesses and widths, depending on the requirements of the end application. These coils can be used for roofing, fencing, electrical appliances, and automotive parts, showcasing their versatility. The galvanized process involves dipping iron or steel into molten zinc, which forms a robust protective barrier against environmental elements.

Choosing a Reliable Supplier

When sourcing galvanized iron coils, selecting a reputable supplier is crucial. A reliable supplier should offer high-quality products, competitive pricing, and excellent customer service. To evaluate potential suppliers, businesses should consider factors such as production capabilities, industry experience, and compliance with quality standards. Additionally, customer reviews and testimonials can provide insights into a supplier's reliability and the overall satisfaction of previous clients.

Factors Influencing Pricing

galvanized iron coil quotes supplier

The pricing of galvanized iron coils can vary significantly based on several factors

1. Material Costs The global prices of raw materials, such as iron and zinc, fluctuate due to market demand and supply dynamics. An increase in raw material costs typically leads to higher prices for finished products.

2. Production Method Different manufacturing processes can affect pricing. The quality of the galvanization process, thickness of the zinc layer, and coating technique can all contribute to the final price.

3. Volume Orders Suppliers often offer discounts for bulk orders. Businesses looking to procure large quantities may negotiate better rates, making it essential to consider order size when calculating costs.

4. Market Demand Seasonal and economic trends can influence the demand for galvanized iron coils, impacting their market value. For instance, a surge in construction projects may drive up demand, resulting in higher prices.

5. Location Transportation costs and logistical considerations also play a role in pricing. Local suppliers may have different costs compared to international ones due to shipping and customs fees.

In conclusion, galvanized iron coils are an integral part of modern manufacturing and construction. By understanding the characteristics of these products and the factors affecting their pricing, businesses can better navigate their purchasing decisions. Selecting a trustworthy supplier and keeping abreast of market trends ensures optimal sourcing for galvanized iron coils, ultimately leading to enhanced project outcomes.

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025