Νοέ . 24, 2024 16:44 Back to list

Corrugated Steel Sheet Manufacturing Facility for Durable Construction Solutions

The Future of Corrugated Steel Sheet Metal Factories

In today’s rapidly developing industrial landscape, the demand for durable, lightweight, and cost-effective building materials has never been greater. Among these materials, corrugated steel sheets have emerged as an essential choice for various architectural and construction applications. The corrugated steel sheet metal factory plays a pivotal role in meeting this demand, producing versatile sheets that have become staples in modern constructions worldwide.

Understanding Corrugated Steel Sheets

Corrugated steel sheets are formed through a rigorous process that involves shaping metal into a series of wave-like ridges and troughs. This design not only enhances the aesthetic appeal of the material but also significantly improves its structural strength. The corrugation process increases the rigidity of the metal while maintaining a lightweight profile. This makes it an ideal choice for roofing, wall panels, and even flooring in both residential and commercial spaces.

One of the key advantages of corrugated steel sheets is their durability. Steel is inherently resistant to various environmental factors, including wind, rain, and snow. In addition, corrugated metal offers excellent corrosion resistance, especially when coated with zinc or other protective layers. This feature makes it a reliable option for long-term use in harsh conditions, reducing maintenance costs and extending the lifespan of structures.

The Role of Factories in Production

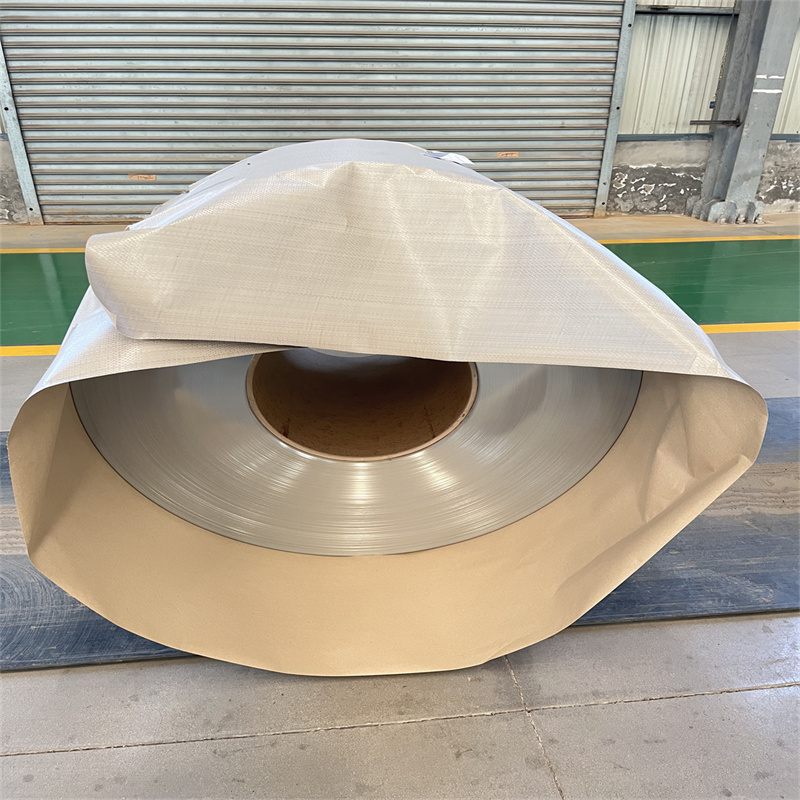

A corrugated steel sheet metal factory is equipped with advanced machinery designed to efficiently produce these sheets at scale. From the initial processing of raw steel to the final packaging of finished products, these factories employ cutting-edge technology to ensure precision and quality. Automated systems for cutting, bending, and forming steel sheets minimize human error and enhance productivity.

Moreover, the factories are increasingly adopting sustainable practices in their operations. Many manufacturers are now prioritizing the use of recycled materials in their production processes, opting for steel that has been repurposed from old structures. This not only decreases the carbon footprint of production but also aligns with global efforts toward sustainability.

corrugated steel sheet metal factory

Innovations and Trends

Innovation is at the forefront of the corrugated steel sheet market. New technologies are continually being developed to enhance the manufacturing process, improve the quality of the sheets, and introduce new finishes and colors. This provides architects and builders with more design options, catering to a broader range of architectural styles.

Additionally, the integration of smart technologies is transforming how corrugated steel sheets are produced and utilized. For instance, factories are increasingly using IoT (Internet of Things) technologies to monitor production lines in real-time, ensuring efficiency and allowing for quick adjustments to meet changing demands. This responsiveness is crucial in an era where customization and speed are vital to client satisfaction.

Challenges in the Industry

Despite the promising growth of corrugated steel sheet metal factories, the industry does face challenges. Fluctuations in raw steel prices can impact production costs significantly. Furthermore, with the rising competition in the market, manufacturers must continually strive to improve their products and streamline their processes to maintain profitability.

Additionally, as the industry moves toward more sustainable practices, factories may encounter obstacles in sourcing recycled materials and implementing eco-friendly technologies. However, these challenges also present opportunities for innovation and evolution within the sector.

Conclusion

Corrugated steel sheet metal factories stand as critical players in the construction landscape, offering strong, lightweight, and sustainable materials that meet contemporary demands. With ongoing innovations and an increasing focus on sustainability, these factories are poised for future growth and transformation. As they adapt to market changes and technological advancements, the corrugated steel industry will continue to evolve, shaping the structures of tomorrow and contributing to a more resilient built environment.

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025

-

China 14 ft Metal Roofing Price Factory | Durable & Affordable

NewsJul.28,2025