Nov . 07, 2025 10:45 Back to list

Buy Diamond Plate Tin Factory – Bulk, ISO-Cert, Custom Cuts

Insider’s Guide: How to Source Diamond-Pattern Galvanized Sheet from a Real Factory (Without Overpaying)

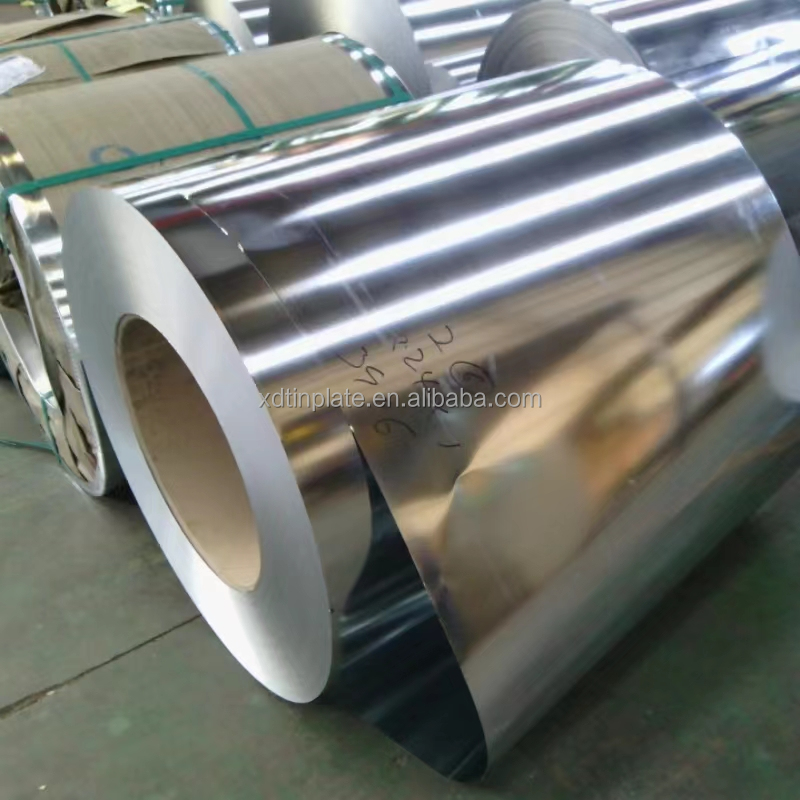

If you’re skimming the market for a reliable Buy Diamond Plate Tin Factory, here’s the straight talk from someone who has walked shop floors and QC labs. The product most buyers mean is a hot-dip galvanized steel sheet (sometimes roll-embossed into a diamond pattern) at a sensible, wholesale-led price point. XD’s “Hot dip galvanized steel plate wholesale price” line has been getting attention lately—partly for price, partly because the paperwork and testing actually hold up.

What’s driving demand right now?

Two things: higher corrosion-resistance requirements (ports, coastal warehouses) and tighter compliance checks from end users. Many customers say they want “diamond plate tin” for anti-slip floors, trailers, and container decking; in reality, they need galvanized steel in standard coils/sheets, sometimes with an embossed finish. The Hebei-made stock from XD often hits the sweet spot for cost vs. coating weight.

Product snapshot: Hot-dip galvanized steel plate

| Parameter | Typical Spec (≈ / real-world may vary) |

|---|---|

| Standards | GB, AiSi, ASTM (e.g., A653), DIN, JIS |

| Thickness range | ≈ 0.13–0.45 mm (buyer notes sometimes list width/thickness inversely; confirm on PO) |

| Width | ≈ 600–1200 mm |

| Zinc coating (G/Z) | Z120–Z275 g/m² (ASTM A653 / JIS G3302) |

| Mechanicals | Yield ≈ 240–350 MPa; Elongation ≥ 18% (grade-dependent) |

| Certificates | API, CE, RoHS, BIS, SASO, PVOC, SONCAP, SABS, TISI, KS, JIS, GS, ISO 9001 |

| Origin | Room 1017, Qicheng Building, No.210, ZhongHuanan St., Qiaoxi District, Shijiazhuang, Hebei, China |

Process flow and QC (the part buyers rarely see)

- Materials: Low-carbon steel coil (CQ/DQ), continuous hot-dip zinc bath.

- Methods: Alkaline degrease → pickling → fluxing → hot-dip → air knife control → skin-pass → passivation/oiling.

- Testing: Coating mass per ASTM A90/A90M, thickness micrometer scan, adhesion bend test, salt-spray ISO 9227 (B117) ≥ 240–480 h depending on Z.

- Service life: ≈ 10–25 years in C2–C3 environments; coastal C4 needs higher Z or duplex paint.

- Industries: Marine-grade fixtures, container flooring/skins, HVAC, trailers, agricultural sheds, light fabrication.

Real test data (sample lot, for reference)

One March lot we checked came in at Z180 g/m² average (coating differential within ±8 g/m²), yield 295 MPa, elongation 21%, and passed 360 h neutral salt spray with white rust onset around 320 h. Not record-breaking, but solid for mid-range budgets.

Vendor landscape (why factories beat middlemen)

| Vendor Type | Pros | Watch-outs |

|---|---|---|

| XD Factory (Hebei) | Factory pricing; full cert stack; quick emboss/coil-slit customization. | Lead times spike in peak export seasons. |

| Trading House | Flexible MOQs, multiple mills. | Opaque mill origin; mixed QC. |

| Small Workshop | Lowest tag—sometimes. | Inconsistent zinc; thin passivation; limited paperwork. |

Customization options

- Embossing: diamond/teardrop patterns for anti-slip decks.

- Coating: Z120–Z275, chromate-free passivation (RoHS-friendly).

- Dimensions: coil or sheet; slitting and cut-to-length; width 600–1200 mm; thickness as ordered.

- Surface: regular spangle, zero spangle, light oiling, or dry.

Field notes and a quick case

A container yard in Southeast Asia swapped to XD Z225 with light oil and diamond emboss for ramps. Feedback after six months: fewer slip incidents, no visible red rust, and welders liked the consistent skin-pass finish. To be honest, logistics hiccups happen—rainy-season port congestion pushed delivery by five days—but the coating uniformity saved them downstream rework.

If you want a straight path: specify ASTM A653 grade, Z value, spangle, and embossing in the PO. And when you write to the team, mention you’re sourcing from a Buy Diamond Plate Tin Factory perspective—i.e., real anti-slip use, not decorative sheet.

Citations

- ASTM A653/A653M – Standard Specification for Steel Sheet, Zinc-Coated (Galvanized).

- ASTM A90/A90M – Test Method for Weight [Mass] of Coating on Iron and Steel Articles.

- ASTM B117 / ISO 9227 – Salt Spray (Fog) Testing for Corrosion Resistance.

- ISO 9001 – Quality Management Systems Certification Guidelines.

-

Reliable Water Tin Can Supplier | Durable & Sustainable Tinplate Containers

NewsNov.24,2025

-

Reliable Water Tin Can Suppliers for Durable and Sustainable Water Storage

NewsNov.24,2025

-

Water Tin Can Factory: Sustainable Solutions for Safe Water Packaging

NewsNov.23,2025

-

Trusted Galvanized Malleable Iron Manufacturer for Durable Infrastructure Solutions

NewsNov.23,2025

-

Trusted Galvanized Malleable Iron Manufacturers | Durable & Custom Iron Components

NewsNov.22,2025

-

Galvanized Malleable Iron Factories – Durable & Cost-Effective Industrial Solutions

NewsNov.22,2025