নভে. . 01, 2024 02:29 Back to list

Tin Mill Black Plate Production and Leading Manufacturers in the Industry

The Importance of Tin Mill Black Plate Manufacturers

Tin mill black plate (TMBP) serves as a critical material in industrial applications, particularly in the packaging, automotive, and construction sectors. This uncoated steel product is the precursor to tinplate, which is commonly used for making cans and other containers. The demand for TMBC has led to the emergence of specialized manufacturers who focus on producing high-quality black plates, catering to various industries around the globe.

TMBC is made from low carbon steel and is characterized by its excellent formability, strength, and resistance to corrosion. The manufacturing process involves several steps, including cold rolling and annealing, which enhance the material's properties. As manufacturers strive to meet the increasing demands for sustainable and durable packaging solutions, the significance of TMBC cannot be overstated. It provides a robust base for coatings that offer even greater protection against the elements.

One of the primary advantages of TMBC is its versatility. It can be easily processed into various shapes and sizes, making it suitable for countless applications. From food and beverage packaging to industrial containers, the black plate can be rolled, stamped, or drawn to meet specific requirements. This flexibility is not only beneficial for manufacturers, who can diversify their product offerings, but also for customers seeking tailored solutions to their packaging needs.

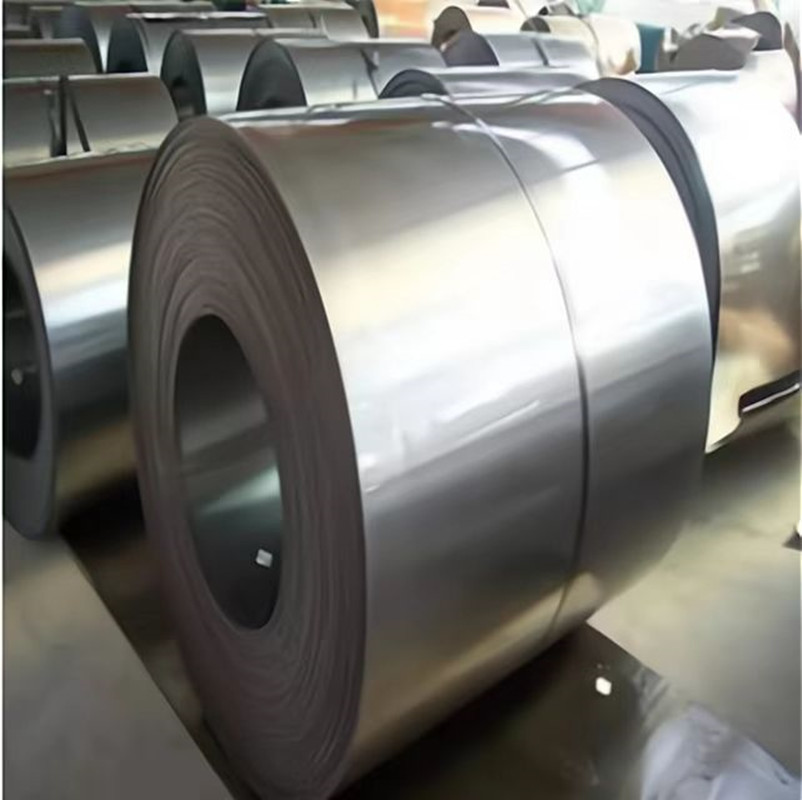

tin mill black plate manufacturers

Manufacturers in the TMBC sector are continuously innovating to improve their production processes and the quality of their products. Advanced technologies, such as automated quality control systems and eco-friendly production methods, are being adopted to enhance efficiency and minimize environmental impact. These changes are essential in today’s market, where sustainability is a growing concern. Customers are increasingly looking for manufacturers that adhere to responsible practices and provide environmentally friendly materials.

Moreover, the competitive landscape of TMBC manufacturing is constantly evolving. Companies are focusing on building strong relationships with suppliers and customers to ensure reliability and maintain quality throughout the supply chain. This collaborative approach not only enhances product quality but also fosters innovation as manufacturers share insights and advancements in technology.

As the global economy shifts towards more sustainable practices, the demand for TMBC is expected to rise

. Manufacturers that adapt to these changes and prioritize quality, innovation, and sustainability will be better positioned to thrive in the marketplace. The role of tin mill black plate manufacturers is crucial in shaping the future of packaging and industrial processes, contributing to efficient, durable, and eco-friendly solutions.In conclusion, tin mill black plate manufacturers play a pivotal role in various industries by providing a fundamental material for many products. Their commitment to quality, innovation, and sustainability will not only meet current market demands but will also pave the way for future advancements in materials and manufacturing processes. As the industry continues to evolve, these manufacturers will undoubtedly remain integral to the global supply chain, driving progress and efficiency in multiple sectors.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025