Nov . 06, 2025 10:20 Back to list

Buy Diamond Plate Tin Factory Direct | ISO Quality, Low MOQ

Buy Diamond Plate Tin Factory: what I saw on the shop floor this year

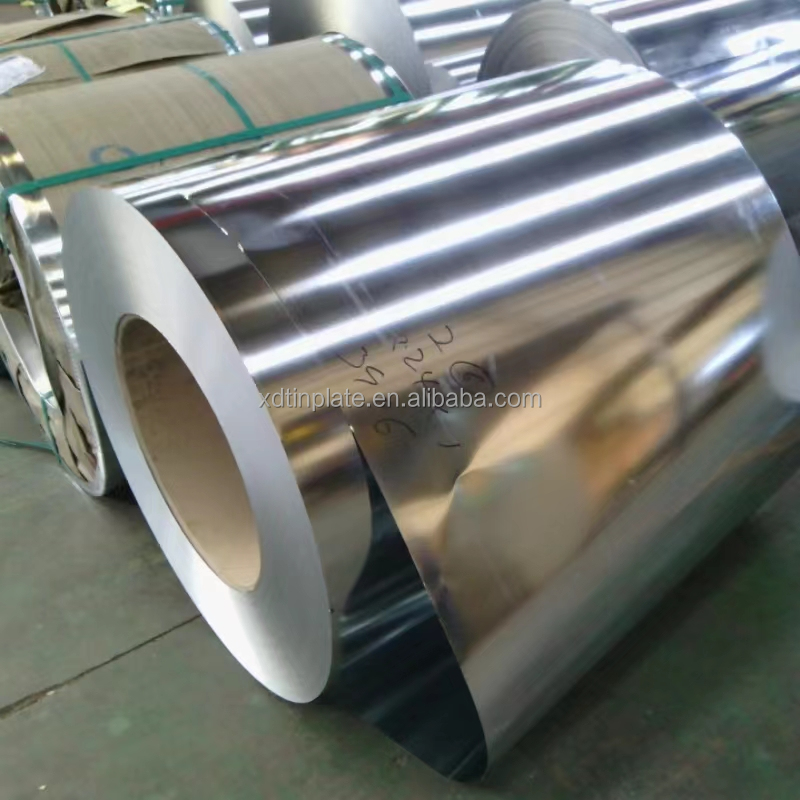

Visiting the XD line in Hebei felt like stepping into a steady heartbeat of steel. Coils come in cold and gray, leave bright and ready for weather. Their “Hot dip galvanized steel plate wholesale price” offer is what many buyers use when scouting a Buy Diamond Plate Tin Factory source for marine, containers, and even embossing lines. To be honest, the market’s noisy; yet this product has been getting surprisingly consistent feedback on coating uniformity and lead time.

Industry trend snapshot

Demand for galvanized sheet tied to containers, port infrastructure, and ag buildings is still strong. Energy projects (solar mounting, cable trays) are nudging specs toward higher zinc classes (e.g., Z275/Z350). It seems that buyers want two things: predictable anti-corrosion life and flexible widths for downstream processing. XD, from Room 1017, Qicheng Building, No.210, ZhongHuanan Street, Qiaoxi District, Shijiazhuang City, Hebei Province, is leaning into that with tight coating control and broad certifications.

Product specs (field notes)

| Base metal | Low-carbon steel per GB/AiSi/ASTM/DIN/JIS |

| Thickness | 0.13–0.45 mm (catalog width also listed 600–1200 mm; real-world use may vary — confirm before PO) |

| Width | ≈ 600–1200 mm (per current listing) |

| Zinc coating | Z120–Z350, typical Z275 for marine/container, tested to ASTM A653/JIS G3302 |

| Surface | Spangle controlled, chromate/passivation, light oiling; skin-pass optional |

| Certificates | API, CE, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, SIRM, TISI, KS, JIS, GS, ISO9001 |

How it’s made (quick process flow)

Materials: prime low-carbon coils → Pickling/cleaning → Continuous annealing → Hot-dip zinc pot → Air-knife coating control → Passivation (Cr-free options available) → Skin-pass → Oiling → Slitting/cutting → Packing. Testing: coating mass per ASTM A653/A924 or JIS G3302; thickness per ISO 2178/ASTM E376; tensile per ISO 6892; corrosion per ISO 9227 NSS. Typical NSS results at Z275: > 480 h to white rust, > 720 h to red rust, lab data; field life ≈ 10–25 years depending on environment and maintenance.

Applications I keep seeing

- Marine-grade panels, pier fencing, and ladders

- Container plate and cold-chain bodies

- Embossed floor “diamond” sheet pre-galvanized feedstock

- Ag buildings, HVAC ducts, cable trays, solar racking

Many customers say the coil shape is steady, which matters when you plan to emboss patterns later without waves.

Vendor comparison (what buyers weigh)

| Vendor | Coating classes | MOQ | Lead time | Certs | Typical price |

|---|---|---|---|---|---|

| XD (Hebei) | Z120–Z350 | ≈ 25–50 t | 10–20 days | API, CE, RoHS, ISO9001 | Market-average −3% to −5% (seasonal) |

| Regional Mill A | Z100–Z275 | ≈ 60 t | 20–30 days | ISO9001 | Baseline (≈) |

| Trading House B | Z80–Z275 | Flexible | 15–35 days | Mixed | +2% to +6% (service fee) |

Customization and QC

Options: custom lengths, coil ID/OD, edge trim, spangle size, RoHS-compliant passivation. QC gates include coating mass checks each coil, flatness map, and adhesion bend test (T-bend 0–2T target depending grade).

Case notes

Coastal container yard, Southeast Asia: Z275, 0.42 mm feedstock for panel work; NSS lab > 720 h to red rust; field touch-ups only at cut edges after 18 months. A port contractor told me, “Delivery was early by four days—saved our crane slot.” That kind of detail matters when you plan a Buy Diamond Plate Tin Factory order around logistics windows.

Bottom line: if you’re shortlisting a Buy Diamond Plate Tin Factory partner, this hot-dip galvanized line checks the spec boxes and the scheduling boxes. Get mill certs with the quote—always.

References

- ASTM A653/A653M – Standard Specification for Steel Sheet, Zinc-Coated.

- ASTM A924/A924M – General Requirements for Steel Sheet, Metallic-Coated.

- JIS G3302 – Hot-dip zinc-coated steel sheet and strip.

- GB/T 2518 – Continuous hot-dip galvanized steel sheet and strip.

- ISO 9227 – Corrosion tests in artificial atmospheres (neutral salt spray).

- ISO 6892-1 – Metallic materials — Tensile testing.

-

Reliable Water Tin Can Supplier | Durable & Sustainable Tinplate Containers

NewsNov.24,2025

-

Reliable Water Tin Can Suppliers for Durable and Sustainable Water Storage

NewsNov.24,2025

-

Water Tin Can Factory: Sustainable Solutions for Safe Water Packaging

NewsNov.23,2025

-

Trusted Galvanized Malleable Iron Manufacturer for Durable Infrastructure Solutions

NewsNov.23,2025

-

Trusted Galvanized Malleable Iron Manufacturers | Durable & Custom Iron Components

NewsNov.22,2025

-

Galvanized Malleable Iron Factories – Durable & Cost-Effective Industrial Solutions

NewsNov.22,2025