ديسمبر . 15, 2024 18:23 Back to list

iron wire galvanized factory

The Galvanized Iron Wire Factory A Pillar of Modern Manufacturing

In the realm of modern manufacturing, the galvanized iron wire factory stands as a crucial establishment, playing a pivotal role in various industries ranging from construction to agriculture. This facility specializes in producing high-quality galvanized iron wire, a product renowned for its durability and corrosion resistance. In this article, we explore the intricacies of galvanized iron wire production, its applications, and the significance of these factories in today’s economy.

Understanding Galvanization

Galvanization is the process of coating iron or steel with a layer of zinc to protect it from corrosion. This method was first developed in the 19th century and has since become a standard practice in manufacturing. The primary objective is to prolong the lifespan of iron products, which are susceptible to rusting when exposed to environmental elements. By adopting galvanization, factories can enhance the quality and longevity of their wire, making it a sought-after material in various sectors.

The Production Process

The production of galvanized iron wire involves several stages, each meticulously designed to ensure the highest standards of quality

1. Raw Material Selection The process begins with selecting high-grade steel wire as the raw material. The quality of the wire is critical, as impurities can affect the final product’s performance.

2. Cleaning and Preparation The wire is then cleaned to remove any oil, dirt, or oxide layers. This is typically achieved through a combination of mechanical scrubbing and chemical treatments, ensuring a smooth surface for galvanization.

3. Galvanization The prepared wire is immersed in a molten bath of zinc. This process allows for the zinc to bond with the iron's surface, creating a corrosion-resistant coating. The thickness of the zinc layer can be controlled, depending on the intended use of the wire.

4. Cooling and Inspection After galvanization, the wire is cooled and undergoes a rigorous inspection process to ensure it meets specified standards. Quality control is imperative, as defects can compromise the effectiveness of the galvanization.

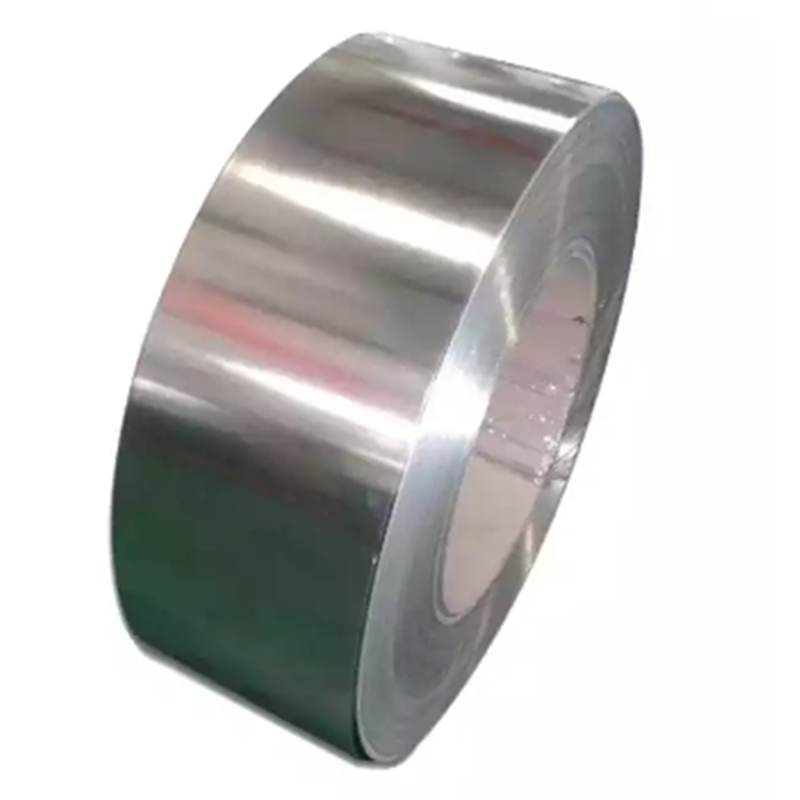

5. Packaging and Distribution Once approved, the wire is coiled, packaged, and made ready for distribution. Efficient logistics are essential to deliver the product to various customers across different industries.

iron wire galvanized factory

Applications of Galvanized Iron Wire

The versatility of galvanized iron wire makes it applicable in numerous fields

- Construction In the construction industry, galvanized wire is widely used for reinforcing concrete structures, fencing, and various types of scaffolding. Its resistance to rust ensures that these components maintain their integrity over time, even in harsh environments.

- Agriculture Galvanized wire is also pivotal in agriculture, used for fencing livestock, trellising plants, and constructing greenhouses. The durability of the wire ensures that it can withstand the rigors of outdoor conditions.

- Manufacturing In manufacturing settings, galvanized wire provides a reliable solution for creating products such as wire mesh, springs, and various industrial components. Its strength and resistance to corrosion make it an ideal choice for applications that require longevity and reliability.

Economic Impact of Galvanized Iron Wire Factories

The presence of galvanized iron wire factories significantly contributes to the economy. They generate employment opportunities, support local businesses, and foster technological advancements in manufacturing processes. Furthermore, as industries seek sustainable materials that can withstand climate challenges, the demand for galvanized products continues to rise.

Additionally, these factories often engage in eco-friendly practices by implementing recycling programs and minimizing waste during production. By reducing their carbon footprint, they contribute positively to environmental sustainability, aligning with global efforts toward responsible manufacturing.

Conclusion

The galvanized iron wire factory is much more than just a manufacturing facility; it is a cornerstone of modern industry that highlights the intersection of tradition and innovation. Through the meticulous production of galvanized wire, these factories not only provide essential materials for construction, agriculture, and manufacturing but also drive economic growth and sustainability. As we look to the future, the role of galvanized iron wire in an increasingly industrialized world will undoubtedly continue to expand, marking its significance in the evolution of manufacturing practices.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025