Feb . 18, 2025 01:57 Back to list

Galvanized steel sheet price hot-dip galvanized

In the vast and competitive landscape of the manufacturing industry, choosing the right materials plays a crucial role in ensuring both the quality and durability of the final products. Among the most reliable materials is galvanized steel, a testament to advanced metallurgy and protective innovation. This article delves into the world of galvanized steel iron manufacturers, spotlighting the expertise and credibility required to thrive and stand out in this specialized field.

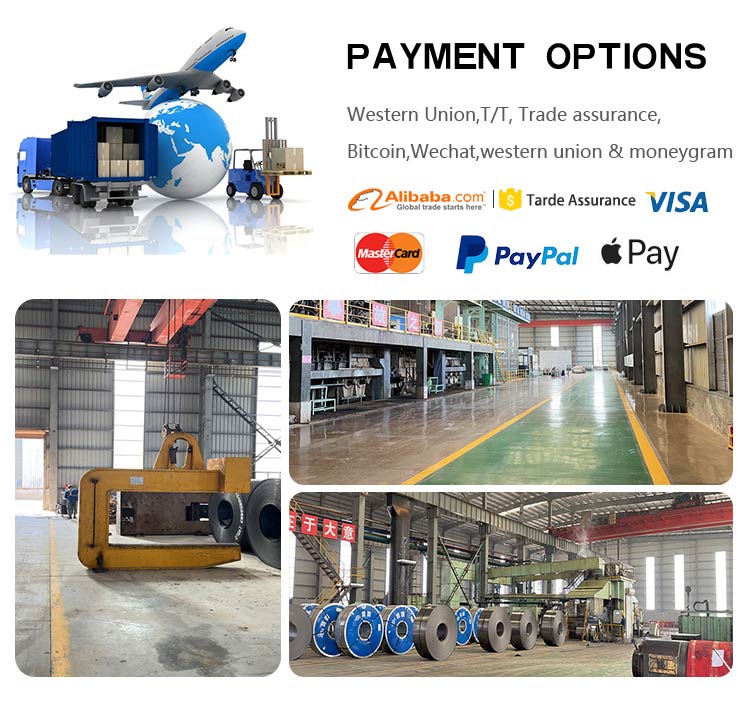

Authoritativeness in the realm of galvanized steel iron manufacturing is established through compliance with international standards. Manufacturers underscore their authority by adhering to certifications such as ISO 9001 for quality management systems and ISO 14001 for environmental management. These certifications assure clients of the reliability and eco-friendliness of their galvanized products. Furthermore, many manufacturers engage in meticulous testing of their products, utilizing salt spray and humidity tests to verify corrosion resistance, underscoring their commitment to quality assurance. Trustworthiness in this industry emanates not only from stringent quality controls but also from transparent business practices. Reputable manufacturers maintain open lines of communication with their clients, providing comprehensive technical support and detailed product specifications. Such manufacturers often pride themselves on cultivating long-term relationships with clients, partners, and suppliers, underscoring a reputation built on integrity and reliability. Testimonials and case studies often reveal how these manufacturers exceed client expectations, further solidifying their standing in the market. In conclusion, the landscape of galvanized steel iron manufacturing is dominated by companies that exhibit exceptional experience, expertise, authoritativeness, and trustworthiness. These manufacturers are not merely suppliers but partners in ensuring the structural integrity and longevity of a diverse range of applications, from construction to automotive industries. By focusing on innovation, quality assurance, and customer satisfaction, these companies not only meet but set the standards in galvanized steel production. As industries demand more sustainable and resilient materials, the role of galvanized steel continues to grow, reaffirming the vital importance and enduring relevance of seasoned manufacturers in this field.

Authoritativeness in the realm of galvanized steel iron manufacturing is established through compliance with international standards. Manufacturers underscore their authority by adhering to certifications such as ISO 9001 for quality management systems and ISO 14001 for environmental management. These certifications assure clients of the reliability and eco-friendliness of their galvanized products. Furthermore, many manufacturers engage in meticulous testing of their products, utilizing salt spray and humidity tests to verify corrosion resistance, underscoring their commitment to quality assurance. Trustworthiness in this industry emanates not only from stringent quality controls but also from transparent business practices. Reputable manufacturers maintain open lines of communication with their clients, providing comprehensive technical support and detailed product specifications. Such manufacturers often pride themselves on cultivating long-term relationships with clients, partners, and suppliers, underscoring a reputation built on integrity and reliability. Testimonials and case studies often reveal how these manufacturers exceed client expectations, further solidifying their standing in the market. In conclusion, the landscape of galvanized steel iron manufacturing is dominated by companies that exhibit exceptional experience, expertise, authoritativeness, and trustworthiness. These manufacturers are not merely suppliers but partners in ensuring the structural integrity and longevity of a diverse range of applications, from construction to automotive industries. By focusing on innovation, quality assurance, and customer satisfaction, these companies not only meet but set the standards in galvanized steel production. As industries demand more sustainable and resilient materials, the role of galvanized steel continues to grow, reaffirming the vital importance and enduring relevance of seasoned manufacturers in this field.

Latest news

-

New Energy Vehicles: High Endurance & Cost-Performance

NewsAug.27,2025

-

New Electric Vehicles: Explore BYD Cars & Future Energy

NewsAug.26,2025

-

Buy Diamond Plate Tin Factory Direct | Quality & Durable Metal

NewsAug.25,2025

-

BYD Electric Cars: Innovation & Performance EVs

NewsAug.24,2025

-

High Cost Performance: Stylish, High Endurance Devices

NewsAug.23,2025

-

Cheap Car & EV Deals: Used, New Energy & Luxury Electric Vehicles

NewsAug.22,2025